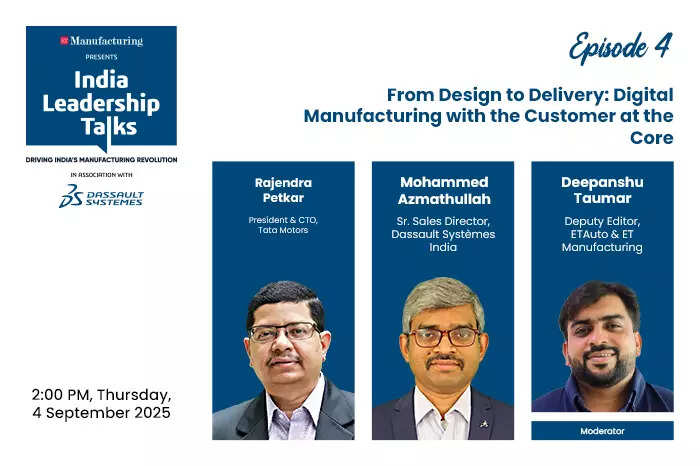

At Tata Motors, innovation isn’t left to likelihood. The corporate has put in place a structured New Know-how Growth (NTD) course of that generates lots of of concepts annually, systematically filters them, and brings solely probably the most impactful ones to market.

“The factors for us are clear. A brand new know-how ought to both be the primary on this planet, the primary in India, or at the least the primary at Tata Motors,” mentioned Rajendra Petkar, President & CTO, Tata Motors. “Cross-functional groups consider each concept with the only real goal of guaranteeing market readiness moderately than permitting lengthy gestation cycles.”

Additionally watch:

Mohammed Azmathullah, Sr. Gross sales Director, Dassault Systèmes India, added that such self-discipline is what makes digital enablement highly effective. He mentioned, “When you have got a structured innovation pipeline, platforms like 3DEXPERIENCE can amplify its affect, guaranteeing each concept may be nearly modelled, examined and refined earlier than transferring into bodily improvement.”

Patents and startup partnerships

The results of this structured course of is a gentle stream of patents and mental property that strengthen Tata Motors’ management in each passenger and business autos. The corporate additionally faucets into India’s vibrant startup ecosystem to develop applied sciences that require longer incubation.“We’ve got a number of boards, from blue-sky pondering to structured NTD processes, which permit us to collaborate with startups,” famous Petkar. “Via these mechanisms, we’ve constructed a robust pipeline of patents and applied sciences that finally attain clients.”

In response to Azmathullah, OEM–startup collaboration thrives when backed by digital twins. “Digital twins speed up co-development by enabling speedy simulation of ideas. This helps startups and OEMs work collectively seamlessly and validate concepts far faster than in conventional fashions.”

Listening to the client early

Buyer enter isn’t an afterthought at Tata Motors however the place to begin of its product introduction cycle. The pre-kick-off stage, which precedes formal improvement, is devoted to intensive buyer immersion throughout highways, mining websites, and metropolis roads. Insights are captured utilizing High quality Operate Deployment (QFD) frameworks and reworked into detailed specs.“In Tata Motors, the pre-kick-off stage is the place we spend most time with clients,” defined Petkar. “Our engineers observe responsibility cycles, conduct interviews, and translate buyer voice into product specs earlier than any programme begins.”

Azmathullah highlighted how digital platforms make these insights actionable. “The 3DEXPERIENCE platform ensures suggestions is embedded early. Digital twins in design, simulation and manufacturability research shut the loop between buyer expectations and engineering outcomes.”

Personalisation and the digital expertise

Immediately’s clients search greater than bodily consolation. They demand digital personalisation throughout the lifecycle. Tata Motors is responding by providing digital instruments that information clients to make the best decisions, from application-specific car specs to immersive AR/VR experiences at showrooms.

“Gone are the times whenever you bought a product and walked away,” mentioned Petkar. “We now take a look at all the buyer journey, from pre-kick-off to showroom expertise, to lifetime worth by recycling and remanufacturing.”

For Azmathullah, this marks a shift from “product expertise” to “expertise of the product.” He defined: “Buyer expertise is not solely about consolation in a car, it’s about how seamlessly digital instruments assist clients personalise, simulate, and work together with the product earlier than and after buy.”

Whereas the shift to customer-centric digital manufacturing is promising, it brings challenges. One lies in capturing the best information factors on the idea stage; one other is guaranteeing sturdy execution throughout design, manufacturing and aftermarket.

Future-ready manufacturing begins now

Episode 4 of India Management Talks underscored a easy reality, manufacturing excellence is not about what OEMs construct, however how seamlessly they combine buyer voice, provider innovation and digital continuity into the journey.

“As CTO, I see our largest alternative in turning complexity into simplicity for the top buyer. If we are able to make superior know-how really feel intuitive, now we have succeeded,” mentioned Rajendra Petkar.

Mohammed Azmathullah added, “The winners of tomorrow will probably be those that lengthen digital continuity throughout the worth chain, connecting design to supply, OEMs to suppliers, and bodily merchandise to digital experiences.”

Collectively, their views paint a future the place buyer expertise isn’t a remaining touchpoint however the beginning line of each innovation.