Conversion of biomass and waste plastic to fuels and chemical substances holds promise to satisfy the worldwide agenda of pursuing a carbon-neutral and waste-free human society. Biomass encompasses all kinds of pure natural supplies, each plant-based and animal-based, that may function potential sources for chemical manufacturing and vitality fuels. The potentials of biomass as a sustainable vitality supply we mentioned in our earlier article right here.

Plastics are largely petroleum derived artificial polymers and extensively utilised in every day life for merchandise reminiscent of packaging, home items, electronics, and clothes contributed to the development of mankind. A few of the extremely used polymers reminiscent of low-density polyethylene, excessive density polyethylene, polypropylene, polyvinyl chloride, polystyrene and polyethylene terephthalate are produced globally and could possibly be the supply for gasoline manufacturing. Plastics are sometimes non-biodegradable and persist in landfills for prolonged intervals and pose substantial environmental considerations. International annual plastic manufacturing exceeds 300 million tons, with little decline anticipated. By 2015, roughly 6,300 million metric tons of plastic had gathered, and with out efficient administration measures, an estimated 1,200 million metric tons of plastic might find yourself in landfills by 2050. In keeping with an American Chemical Society Journal article, recycling plastic can successfully handle plastic waste administration points whereas producing priceless merchandise. If worldwide plastic waste could possibly be recycled utilizing environment friendly chemical recycling know-how, it might save about 3.5 billion barrels of oil yearly, equal to USD 176 billion.

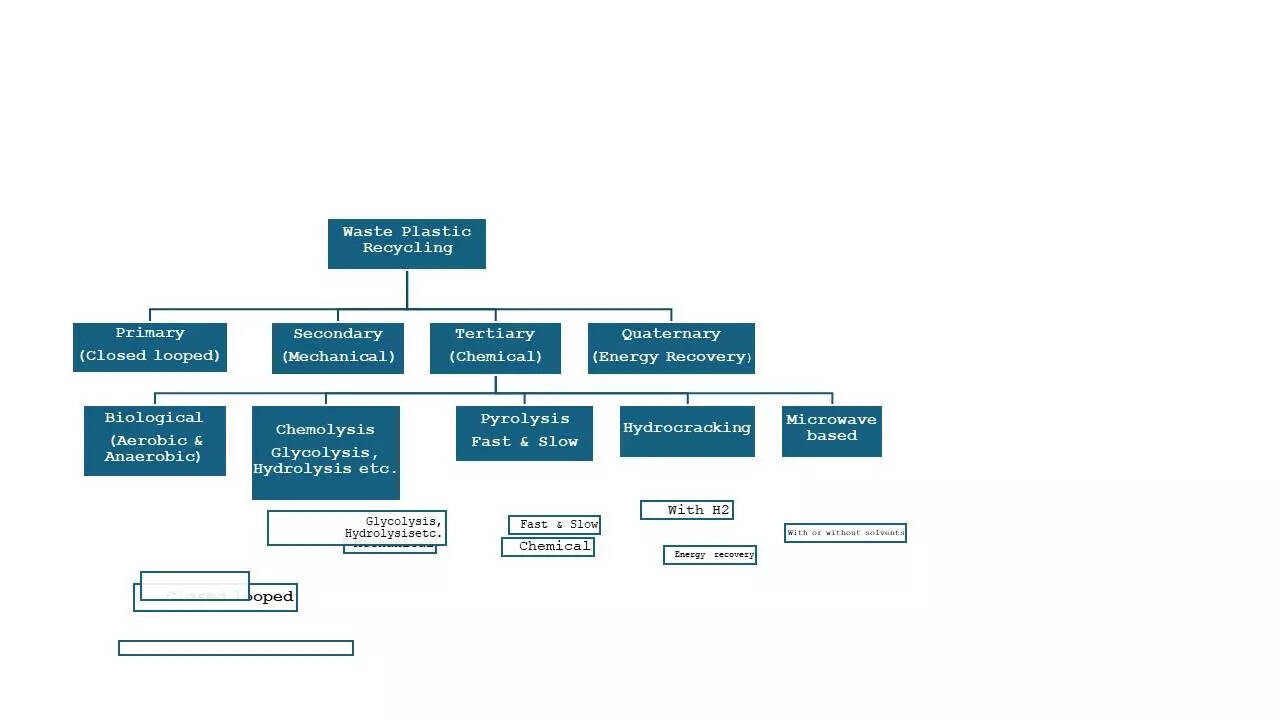

Plastic disposal is a significant concern for humankind and is primarily recycled in numerous methods, specifically main (closed loop), secondary (mechanical), tertiary (chemical recycling), and quaternary (vitality restoration by incineration), as proven in Determine 1. Main recycling reintroduces the used materials into the identical materials, whereas secondary recycling converts it into new plastic merchandise via mechanical processes. Tertiary or chemical recycling produces small molecules from waste plastics, which could be a potential feedstock for fuels, chemical substances, and new polymers. Globally, many chemical processes exist, together with gasification, hydrocracking, pyrolysis, hydrolysis, and methanolysis and so on. Quaternary recycling, or vitality restoration, entails the incineration of waste plastics and the restoration of vitality via the era of warmth and/or electrical energy.

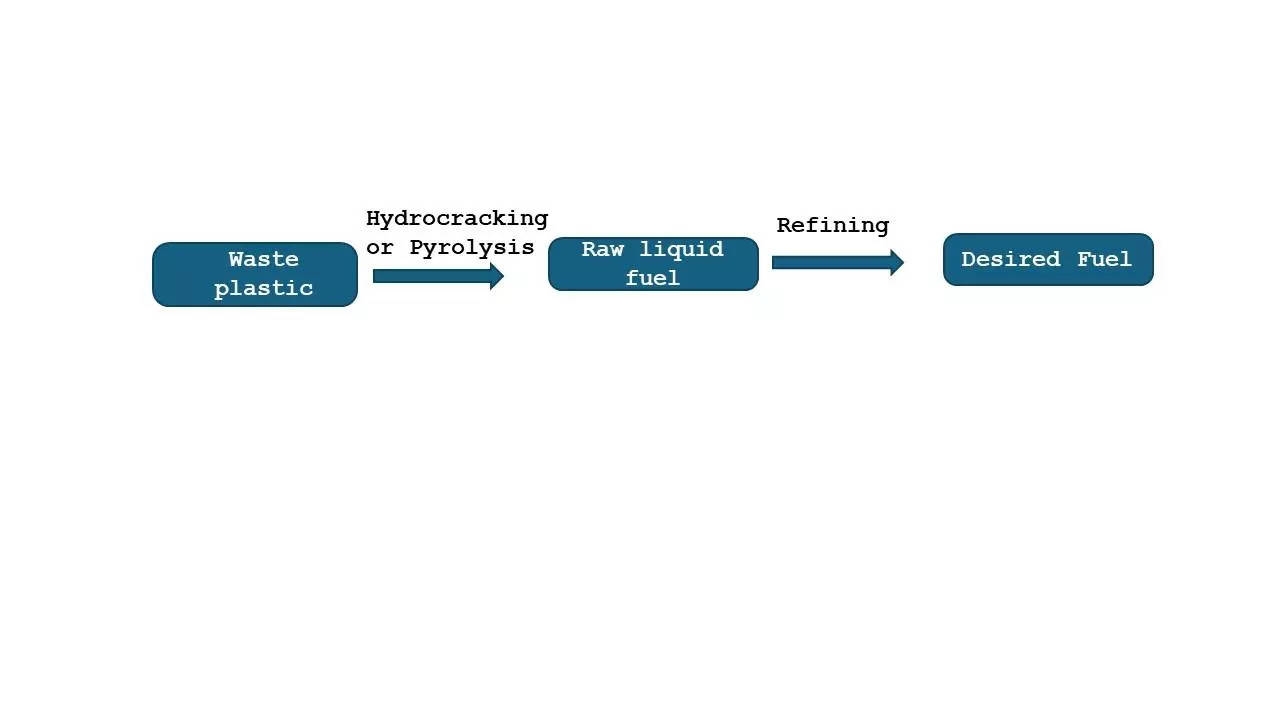

Within the twenty-first century, appreciable efforts have been made to transform biomass and plastic waste into value-added merchandise. Nonetheless, a more in-depth take a look at these supplies reveals compositional and structural similarities, reminiscent of these between a chunk of wooden and a disposable masks. Researchers have developed thermochemical strategies for each biomass and plastics to transform them into hydrocarbons, notably for petrol, jet gasoline, diesel, and lubricants, relying on their carbon-chain size and n/iso-paraffin ratios. These fuels may be produced by treating numerous plastic wastes as feedstock supplies utilizing pyrolysis or hydrocracking methods. Determine 2 reveals a generalised scheme for producing fuels from waste plastic. In step one, waste plastic is depolymerized by pyrolysis or hydrocracking to acquire a uncooked liquid gasoline, which is then additional refined to supply the specified gasoline. In pyrolysis, the feedstock is handled in an inert environment (e.g., nitrogen gasoline, N2) within the presence of catalysts or thermally. Pyrolysis has been established as a confirmed know-how for the oil and gasoline industries. Hydrocracking makes use of hydrogen stress (3-10 MPa) at average temperatures (150-400 °C) to deal with plastic waste with a catalyst within the presence of hydrogen, producing high-quality petrol. The pyrolysis of high-density polyethylene (HDPE) utilizing ultrastable-Y-zeolite as a catalyst produces hydrocarbons within the gasoline vary (C4-C12).Hydrocarbons with boiling ranges of 35–190 °C can be utilized as motor gasoline, these between 190 and 290 °C are appropriate for diesel #1, and people starting from 290 to 340 °C are used as diesel #2. Potential feedstock for gasoline manufacturing embody PE, PP, polystyrene (PS), PET, and PVC, which have a standard calorific worth for gasoline oils of 20900 Btu/lb. Each cracking and pyrolysis break the polymer chains into helpful low molecular weight compounds by heating within the absence of oxygen. Just lately, researchers confirmed that plastic waste could possibly be transformed into ultra-low sulfur diesel (ULSD). ULSD, often known as clear diesel, accommodates 15 ppm or much less sulfur and is presently produced from crude oil.

Sustainable aviation fuels (SAFs) that are basically a kerosene presently derived from petroleum are thought of to be a significant hurdle to reaching internet zero CO2 emissions in aviation. India’s authorities has set a objective of 1% SAF in jet gasoline for worldwide flights by 2027, with this proportion doubling to 2% by 2028. To realize these targets, the nation would require roughly 140 million liters of SAF yearly. In an effort to switch fossil-derived aviation fuels, hydroprocessed esters and fatty acids (HEFA) produced from greases, oils, and fat are anticipated to be the preliminary dominant pathway for producing artificial paraffinic kerosene (SPK). Throughout this time, waste, agricultural and forest residues in addition to alcohol pathways will make solely a modest contribution. (https://pib.gov.in/PressReleaseIframePage.aspx?PRID=1925417)

A minimal of 8.4 vol. proportion of aromatics that may be included with out stranding the remaining paraffins fraction in present plane and different infrastructure. Swelling of elastomer O-Rings in gasoline programs is primarily as a result of aromatics. Constant swelling is crucial to make sure the seal doesn’t lose its integrity and leak gasoline. Crude oil-derived aviation fuels include a mean of 8-20% aromatics. Whereas SPK is a much less fragrant content material (lower than 0.5 vol %) hydrocarbon gasoline made primarily from iso-paraffins and paraffins. On account of this limitation and others (e.g., density), SPK is often restricted to 50% by quantity in a petroleum-derived Jet A mix. The mixing restrict: a restrict to greenhouse gasoline (GHG) financial savings in flight. To extend the mix quantity of SPK, and thereby assist cut back GHG emissions, fragrant molecules may be included from renewable assets together with each biomass or waste streams reminiscent of plastics.

In keeping with a current article revealed by a bunch of researchers from Illinois Sustainable Know-how Heart, College of Illinois at Urbana-Champaign and United States Division of Agriculture-Agricultural Analysis Service (USDA-ARS) in American Chemical Society journal ACS Sustainable Chemistry and Engineering, Ethylbenzene could possibly be used as a gasoline additive in artificial paraffinic kerosene which is used as a non-petroleum based mostly Jet Gasoline. Polystyrene is utilized in shopper/institutional items, packaging, electrical and digital items, furnishings, constructing/building, transportation in addition to industrial/equipment. A lot of the polystyrene turns into waste, forming a supply which may be transformed to aromatics.

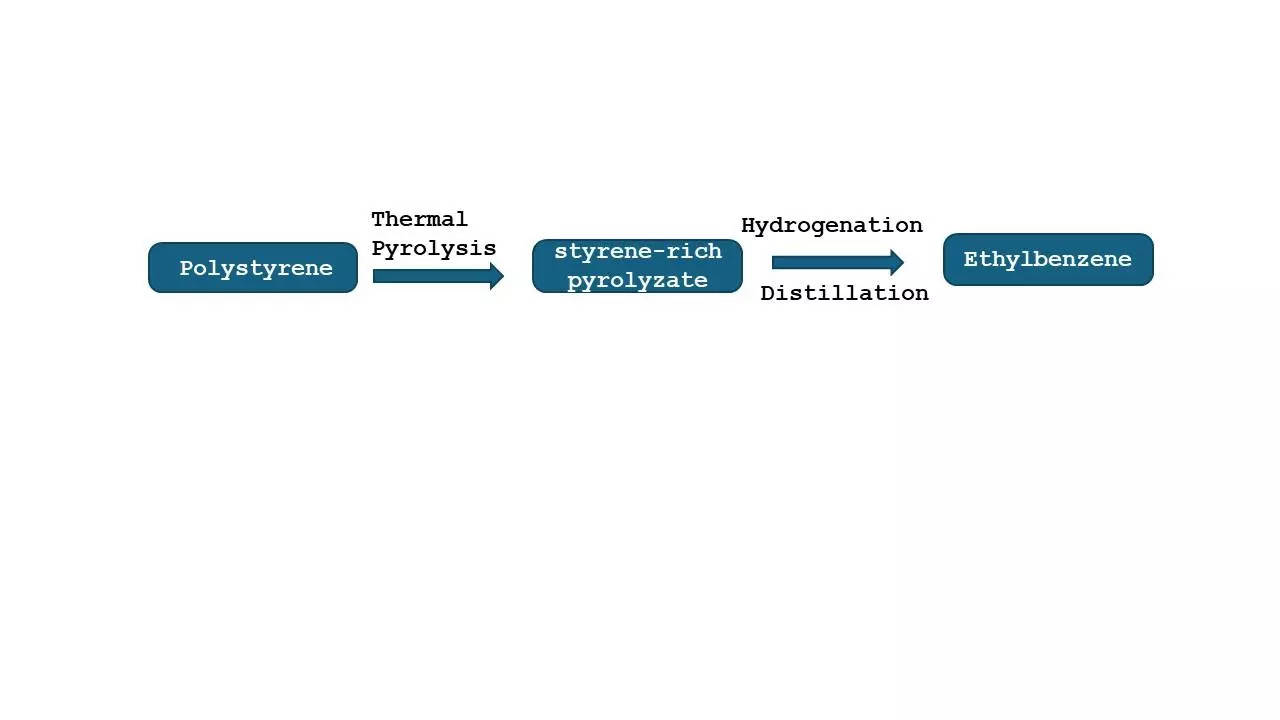

Determine 3 reveals the ethylbenzene manufacturing the place pyrolysis of Polystyrene beads at elevate temperature (375-400 oC) produces a styrene wealthy liquid which additional hydrogenated (50 bar H2 for 1h) to offer ethylbenzene. Distillation of the produced liquid ends in 90 % purified polystyrene. The addition of ethylbenzene (16.5 % v/v) instructed to be advantageous to take care of the ASTM specs of Jet gasoline. This research gives a pathway to deal with the dual problems with plastic air pollution and SPK property enchancment.