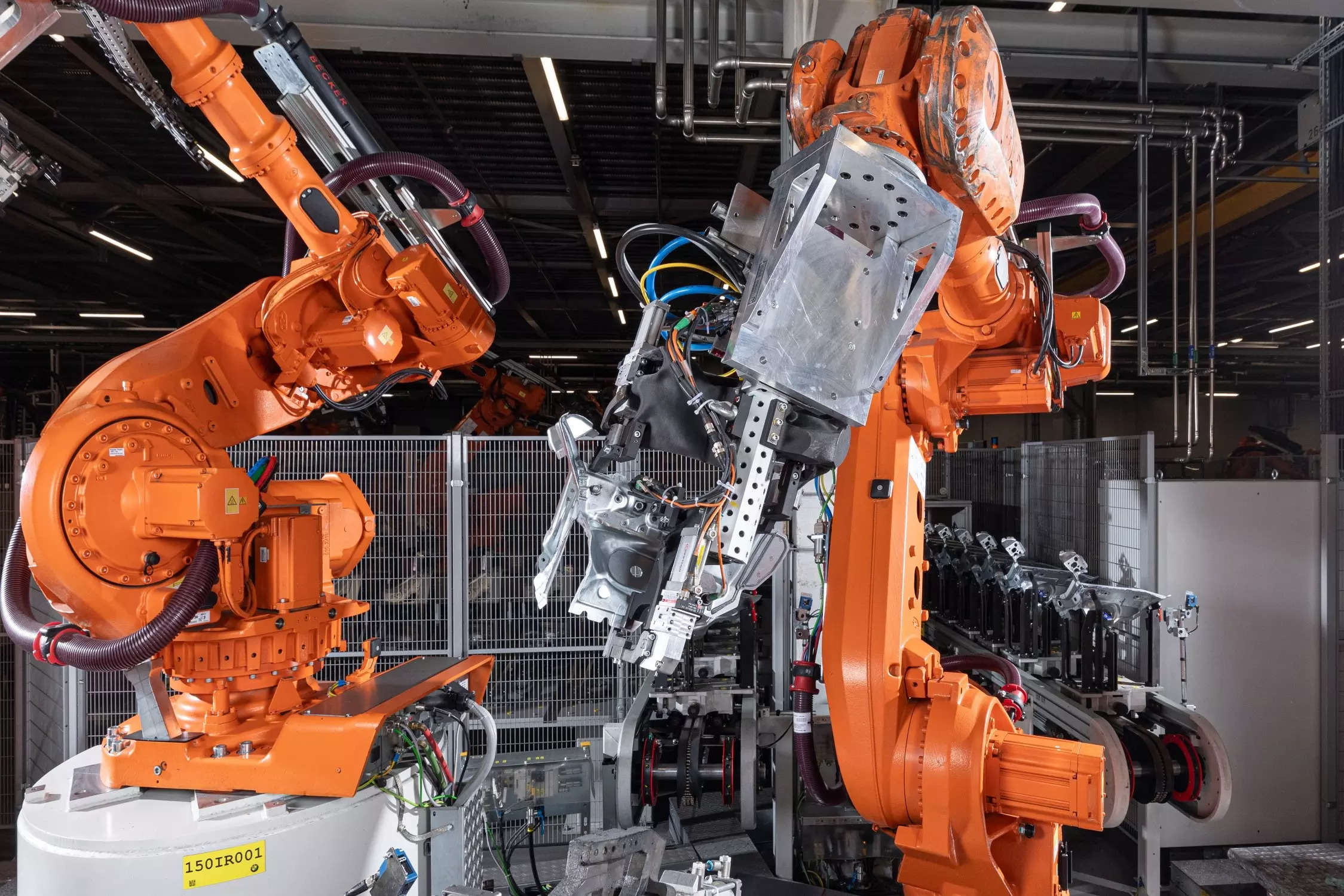

New Delhi: BMW Group has superior its manufacturing course of by integrating customized 3D-printed gripper robots at its Munich plant, considerably boosting effectivity on manufacturing strains, together with these assembling the BMW i4. These progressive bionic grippers are 30% lighter than conventional fashions, dealing with hundreds as much as 110 kilograms, which will increase load capability and reduces carbon emissions.

The brand new grippers are additionally being utilized in different BMW vegetation, using selective laser sintering and large-scale printing for duties akin to managing CFRP roofs on BMW M GmbH fashions. In 2023, BMW’s give attention to additive manufacturing resulted in over 400,000 components produced utilizing this expertise.

Jens Ertel, Head of BMW Additive Manufacturing, emphasised the advantages of this method, together with faster manufacturing of specialised instruments and robots, value discount on manufacturing strains, and general effectiveness. This technique underscores BMW’s dedication to leveraging additive manufacturing for sustainable and high-performance automotive options globally.