New Delhi: Continental has entered a strategic partnership with Munich-based high-tech firm DeepDrive to develop core applied sciences for electrical autos. As a primary milestone, each the businesses will collectively develop a mixed unit comprising drive and brake elements for mounting straight on the car wheel.

DeepDrive is a specialist within the improvement of environment friendly electrical motors, with a few years of expertise in large-scale car manufacturing. Continental, in flip, contributes its technological know-how in brake programs and its experience within the industrialization of modern applied sciences.

“With DeepDrive, we now have gained a powerful associate with whom we will collectively and sustainably advance the market penetration of electrical mobility,” Matthias Matic, head of Continental’s Security and Movement enterprise space, stated. “The electrical motors developed by DeepDrive lengthen the vary of electrical autos. They’re lighter, extra economical, and extra useful resource environment friendly. Combining all that with our environment friendly, high-performance brake know-how to supply a brand new, compact unit is a decisive contribution to the success of electrical mobility. What belongs collectively grows collectively right here.”

“We’re satisfied that the event of our dual-rotor motor will revolutionize the electrification of motor autos,” Felix Poernbacher, co-founder and managing director of DeepDrive, stated. “The strategic partnership with Continental makes it doable to mix our drive system with the brake know-how wanted to create an modern electrical element important to the mobility of tomorrow. The hovering demand for such know-how demonstrates that that is the fitting approach to go.”

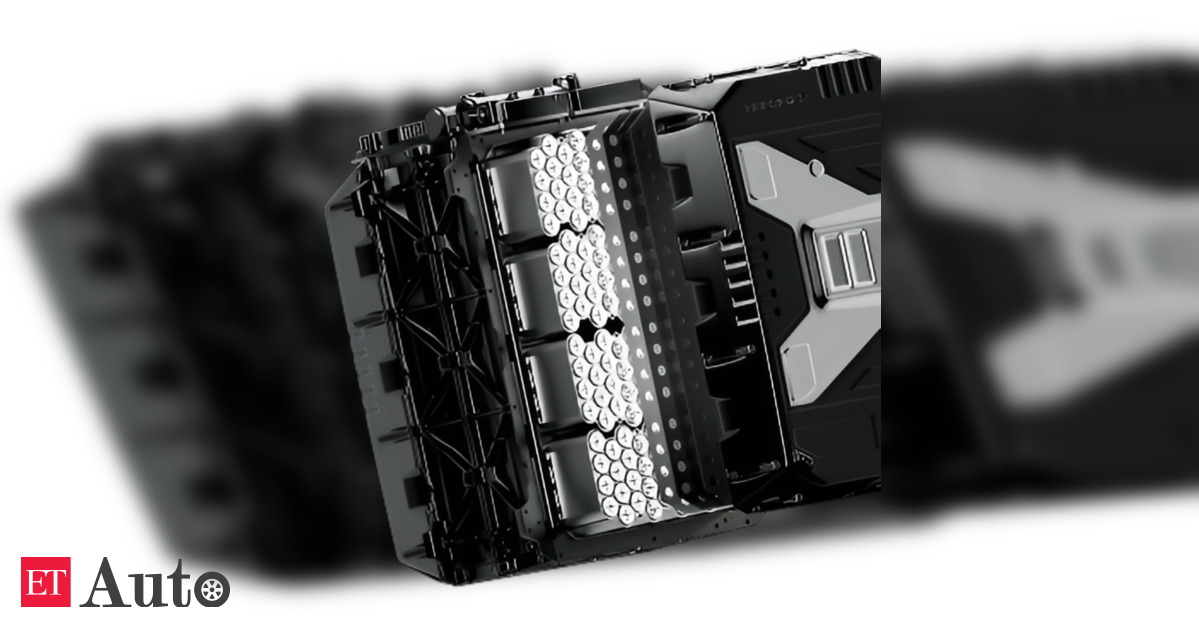

Each the businesses see nice potential of their collaboration because the electrification of autos makes it doable sooner or later to put all chassis features, together with the drive, straight on the wheel. As a way to greatest implement the totally different necessities of electrical autos, similar to maximizing the vary whereas minimizing set up house and simultaneous modularity, complete optimization at car stage is important. The optimum coordination of brake and drive system makes a decisive contribution right here. The combination of each parts in a single unit permits a very excessive stage of effectivity within the drive and when braking. Furthermore, built-in elements scale back complexity via modularization and facilitate the manufacturing course of.Modern drive-brake unit: The Modern drive-brake unit is extra environment friendly, extra compact, and extra economical. DeepDrive has developed and patented what known as a dual-rotor, radial-flux motor that may be put in as a central drive unit or as a wheel hub drive in sequence manufacturing autos. The partnership is specializing in creating an environment friendly, compact wheel hub drive optimized with a view to cost-effective manufacturing. And Continental is contributing not solely brake elements for the joint drive-brake unit.

With its experience in industrializing merchandise proper via to sequence improvement, the corporate is making certain that the motor innovation from Munich will likely be road-ready with state-of-the-art brake know-how quickly. In step one, a hydraulic brake is built-in into the drive-brake unit. In a second step, it is usually deliberate to combine the long-term dry braking programs with out hydraulic elements into DeepDrive’s modern wheel hub drive. The mixture of drive and brake in a single unit can also be step one in direction of a so-called nook module with built-in chassis elements, similar to air suspension programs from Continental, in a compact unit straight on the wheel.

The collaboration between the businesses was initiated by Continental’s Company Enterprise unit (co-pace). The Company Enterprise unit additionally participated within the Munich-based firm as a monetary investor in a Collection-A financing of DeepDrive that was accomplished firstly of the yr.