Globally, there’s a wave of know-how disruption within the vitality and transportation industries. Though clear energy technology applied sciences similar to photo voltaic photovoltaic (PV) and wind generators, and clear transportation applied sciences similar to electrical automobiles, gas cells, and so on., have been round for a very long time, till just lately their industrial viability was questionable.With the rise of their scale of manufacturing, the prices have plummeted previously few years. Nonetheless, for sustained massive scale deployment, availability of low-cost, dependable, secure, and sustainable vitality storage options may be very crucial. Among the many mechanical, thermal, pumped hydro or chemical routes of vitality storage, batteries — electrochemical route of vitality storage – are essentially the most most well-liked.

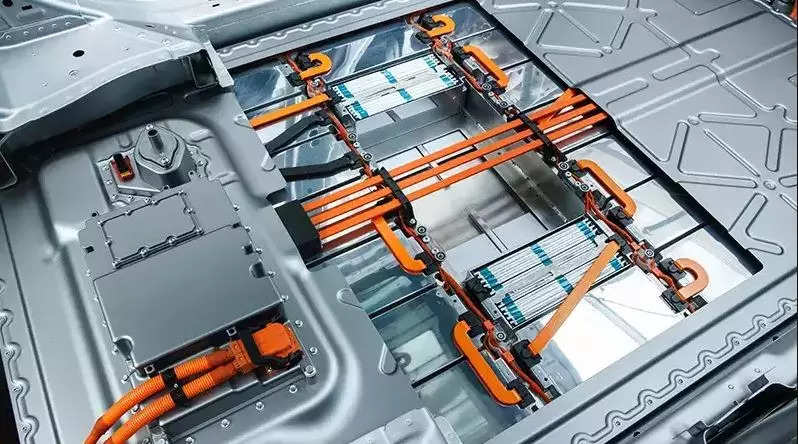

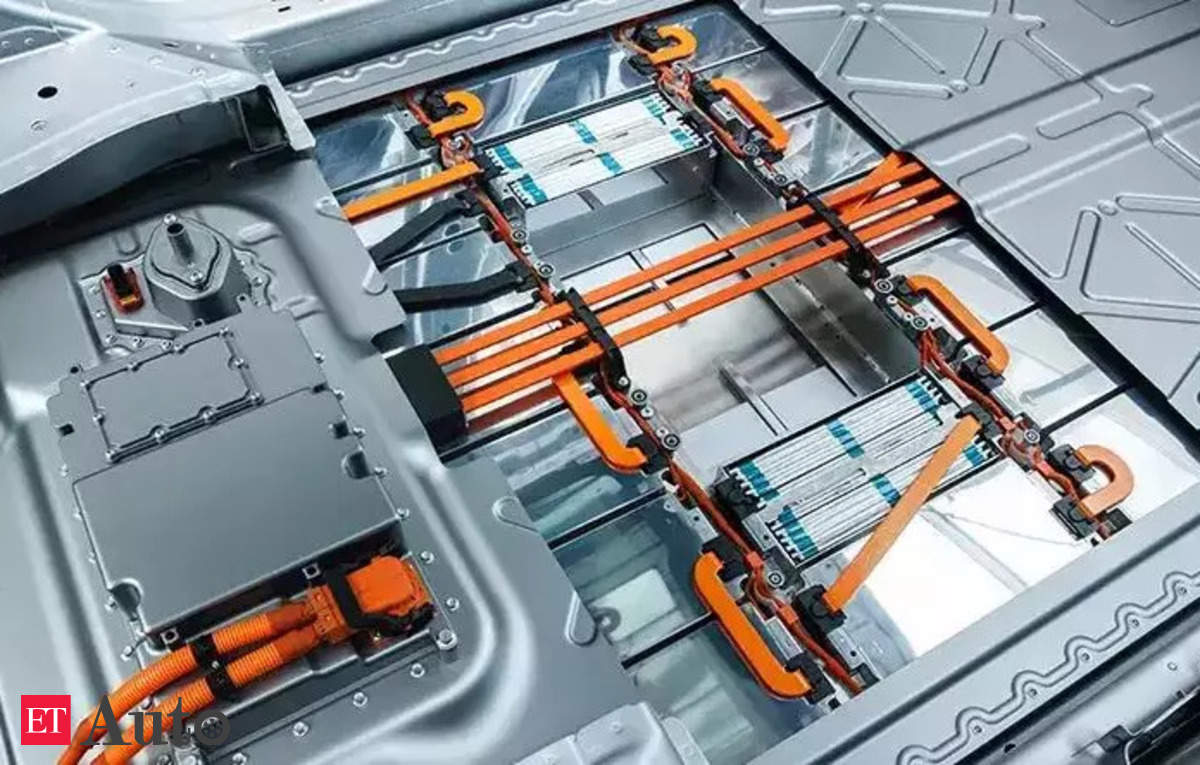

Electrical automobiles require batteries which are secure, compact and sturdy. Photo voltaic/wind energy vegetation require low-cost batteries to retailer and deploy vitality generated throughout their peak hours over longer durations. So batteries have develop into the important thing driver for the development to a clear and carbon- impartial economic system.

Lithium-ion battery

Right now, Lithium-ion battery is the workhorse battery know-how. China has virtually a monopoly on the whole worth chain of Lithium-ion batteries. Contemplating India’s clear vitality targets (to 30% of automobiles to EVs by 2035 and >500 GW of renewable energy), the projected battery demand by 2030 is near 500 GWhr. So the entire challenge of availability of battery supplies and know-how for battery manufacturing has develop into very crucial for vitality safety and self-sufficiency.

It’s turning into more and more evident that the nations which have entry to battery supplies and might manufacture batteries for electrical automobiles may have nice economical and geopolitical benefits. Superpowers just like the US, China and different EU nations are being extraordinarily aggressive in securing mines of strategic minerals in Africa, Afghanistan and different beneath developed/creating and politically unstable nations.

The latest Pandemic and the Russia-Ukraine conflict have additionally given rise to establishing native provide chain and friend-shoring. On high of this, as a way to obtain carbon neutrality, ideally an in depth loop economic system of mining, refining, cell manufacturing, battery packaging, system integration, and battery recycling, all needs to be inside a 300-mile distance.

Aside from mining and refining, the superpowers are positively constructing the remainder of the loop regionally to cater to their native wants. China is many years forward on this race, whereas western nations are attempting to catch up. Therefore for nations like India, given the bold clear vitality/transportation targets and steep native calls for, constructing self-sufficiency for batteries is extraordinarily essential.

This text tries to take a holistic view of what’s wanted for India to attain self-sufficiency in vitality storage/batteries if electrical car targets are to be met by 2030.

On this context we’ll focus on the crucial elements of changing lithium reserves to battery grade supplies, in addition to different battery choices for automobiles past Lithium.

From Lithium reserves to batteries

Traversing the Journey from Lithium reserves to Lithium Batteries entails distinct equally essential steps – materials availability and processing knowhow.

Supplies: For the reason that latest discovery of lithium sources in Jammu-Kashmir and Rajasthan there was quite a lot of dialogue surrounding how this could alleviate the burden of importing Lithium uncooked supplies and enhance Lithium-ion battery manufacturing in India. To grasp this, let’s first check out the standing of world provide and demand of Lithium and different crucial supplies utilized in batteries for electrical automobiles.

The worldwide demand for Li-ion batteries for electrical automobiles is projected to be as much as 2-4 TWhr per 12 months by 2030. This corresponds to international demand of Lithium manufacturing to be round 1-2 million tons and that of Cobalt to be 300-500 Kiloton. Out of this, the projected demand in India for Lithium and cobalt might be ~200 kiloton and ~50 kiloton, respectively. (Cobalt is required just for Lithium batteries that use Nickel-Manganese-Cobalt Oxide as cathodes, and never for the Lithium-ion batteries that use Lithium Iron Phosphate as cathodes). So the query is whether or not we will make 200 kilotons of Lithium yearly 2030 onward.

There are two essential concerns and terminologies which are used on this context, that’s of Lithium Sources and Lithium Reserves. Sources refers back to the whole potential availability of Lithium. They’re deposits that aren’t accessible on the given time. Sources are categorized in three phases based mostly on the geological state of information: G3-Inferred, G2-Indicated and G1-Measured.

Reserves signify the quantity of Lithium that may be technically and economically extracted. Presently Lithium reserves are sometimes ~ 1/3rd that of the Sources. Over the previous few years, globally recognized or inferred (G3) Lithium sources have elevated remarkably because of on-going explorations. Lithium sources are ample to cater to the worldwide demand (refer determine 1a). Presently, the lithium present in India in Jammu-Kashmir and Rajasthan are categorized beneath G3 and G2 class, respectively. Assuming that G1 degree evaluation is at par with G3, with the potential 5.9 million metric tons (MMT) from Jammu-Kashmir and comparable from Rajasthan, India will rank among the many high 5 main nations. It’s actually promising.

In India Lithium mining is regulated by Mines and Minerals Act, 1957 and by Atomic Minerals Concession Guidelines 2016. Typical timelines for extraction are greater than 5 years, so quickly transferring from G3/G2 to G1 state and thereafter extracting Lithium might be our very first step in the direction of self-sufficiency.

Not solely Lithium

However Lithium isn’t the one crucial mineral utilized in Lithium-ion Battery. Other than Lithium, Cobalt, Nickel, Copper and Graphite are additionally crucial minerals for making Lithium-ion batteries. The Republic of Congo holds nearly all of Cobalt. Latin America has >40% Copper and >20% Nickel. And as the US and the European Union are specializing in these sources to diversify their provide chain away from China, governments of Chile, Mexico, and Brazil are attempting to take again management and to nationalize their sources. Alternatively, battery grade Graphite is usually mined solely in China.

So it is extremely essential to try the place we stand on the subject of these supplies. India will definitely should discover and line up these minerals together with Lithium.

Within the subsequent half we’ll see how China has full management over refining/processing of mined crucial minerals used for making Lithium-ion Batteries, and what choices do we’ve to work round this problem.

(Finish of Half 1)

(Disclaimer: Ravi Pandit is the co-founder and Chairman, KPIT Applied sciences. Dr. Sarika Kelkar, Senior Programs Lead, KPIT Applied sciences. Views expressed within the article are private.)

![2023 BMW M2 vs Audi RS3 [Throttle House] 2023 BMW M2 vs Audi RS3 [Throttle House]](https://www.bimmerpost.com/storyimages/48c442f9-27e9-39aa.jpg)