Matlab and Simulink are software program functions which are used throughout sectors, however particularly within the automotive and aeronautical industries. Which is why engineers fascinated by creating merchandise for these industries ought to change into proficient in utilizing them.

“It’s extremely seemingly that the embedded software program in any automobile that you just drive right this moment is developed utilizing our instruments,” says Prashant Rao, head of utility engineering in India at MathWorks, the corporate that developed and sells Matlab and Simulink.

Rao says all the highest 10 automotive and aerospace corporations use their instruments. “In these domains, the utilization of our instruments is a part of the usual workflow for creating methods,” he says.

Matlab is a high-level programming language that expresses matrix and array arithmetic immediately. Engineers should be good in arithmetic and statistics to make use of it. Simulink is a Matlabbased platform used to mannequin and simulate bodily methods – just like the aerodynamic drag on a airplane element, for instance. Tesla is claimed to have constructed Matlab fashions over a few years to know the place all of the battery power flows, after which tweaks the automobile {hardware} to extend effectivity, and subsequently, vary.

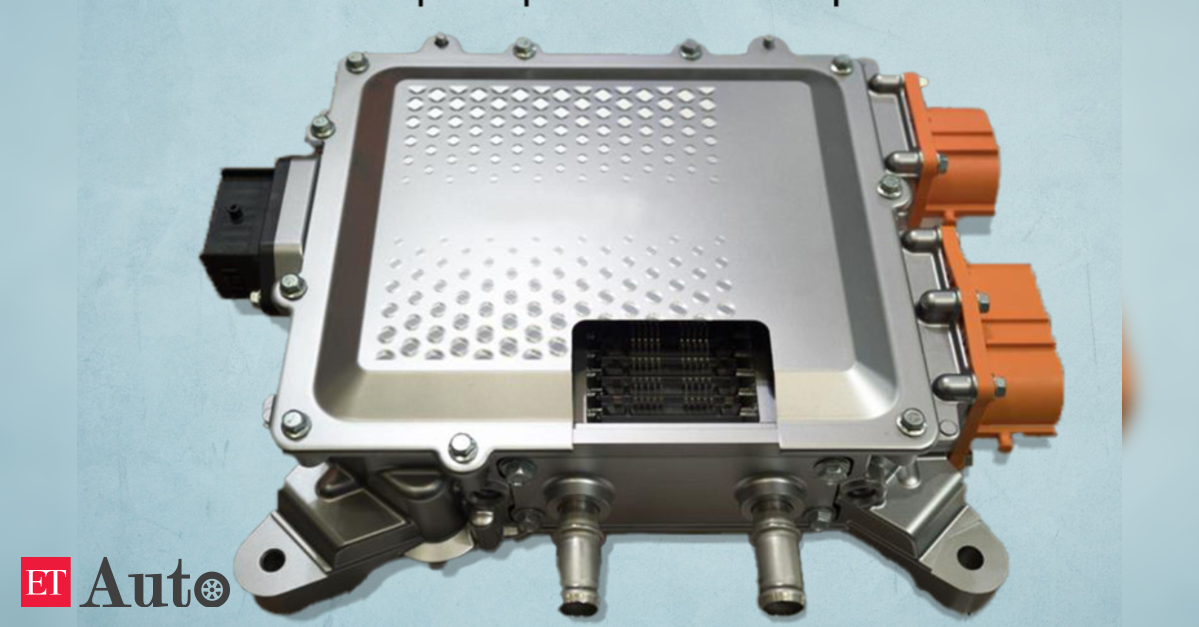

Jacob Peter, senior VP at Bosch World Software program Applied sciences (BGST) in India, says model-based design instruments like Matlab and Simulink present a mathematical and visible strategy to develop advanced management methods. Bosch’s engineers use them to, as an example, speed up embedded controller improvement and calibration. “To develop exhaust gasoline and air system modules, we want temperature and strain inputs from varied positions of the consumption and exhaust sides of the car. Including sensors in all these locations would add quite a lot of value, which is why a model-based strategy that includes Simulink is used,” he says.

Peter says these instruments have change into notably precious due to ever-changing design necessities and stringent timeto-market targets. “They allow our builders to find defects and design issues within the early levels of a mission. They help fast adaptation, quick iterations. In addition they cut back the dependency on {hardware} to carry out verification and validation,” he says.

S Govindarajan, who labored at Tata Motors for 38 years earlier than retiring in 2015, says that whereas designing the Tata Nano, engineers used instruments like Matlab and Simulink to design a totally new engine administration system (EMS) to satisfy the bold value and effectivity targets for the small automobile. “Mannequin-based design enabled us to quickly develop a prototype engine and EMS, consider design alternate options, and refine necessities for the manufacturing {hardware} and software program,” says Govindarajan, who’s now advisor at e-bike methods maker Falco eMotors.

.jpg&c=0)