Tokyo:

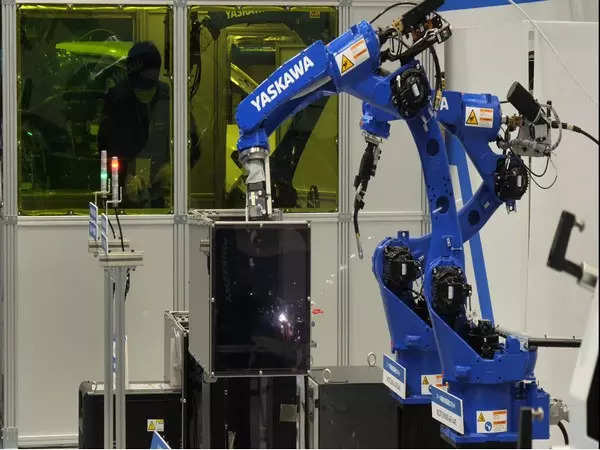

Japan’s Yaskawa Firm has developed an Industrial robotic with synthetic intelligence which determines the color and form of the objects and transports them to their appropriate place.Yaskawa firm is evolving in varied fields, together with the car business and components manufacturing, in keeping with the wants of the period.

“Within the present manufacturing business, as a result of affect of the Corona Pandemic, “contact” has change into troublesome. Additionally, the scarcity of labour is the topic. Professionals with superior expertise are ageing, and their expertise can’t be transferred to the following technology. We wish to make progress in its automation. We want a multi-product manufacturing answer relatively than easy mass manufacturing,” stated Yoshimitsu Sonohara, a Yaskawa Electrical Official.

Yaskawa is selling the answer idea “i3 (i-cube) Mechatronics” to understand a brand new industrial automation revolution.

i3 imply “built-in, clever, modern”.

On the industrial robotic expo held in Tokyo this March, an indication introducing Yaskawa’s newest know-how attracted consideration.

Within the demonstration, robots with completely different roles work correctly. Every robotic has synthetic intelligence and works independently. The trainer robotic provides environment friendly directions to every robotic a few work state of affairs.

The robots additionally talk with one another to work autonomously and extra effectively.

“The subsequent robotic doesn’t co-exist with individuals, however works independently, and enhances its judgment and workability by using the gathered knowledge. We consider that the idea of “i3 (i-cube) Mechatronics” might be utilized to manufacturing around the globe,” Yoshimitsu Sonohara, one other Yaskawa Electrical official stated.

Yaskawa Electrical’s know-how has the mission to help the worldwide manufacturing business repeatedly.