New Delhi:

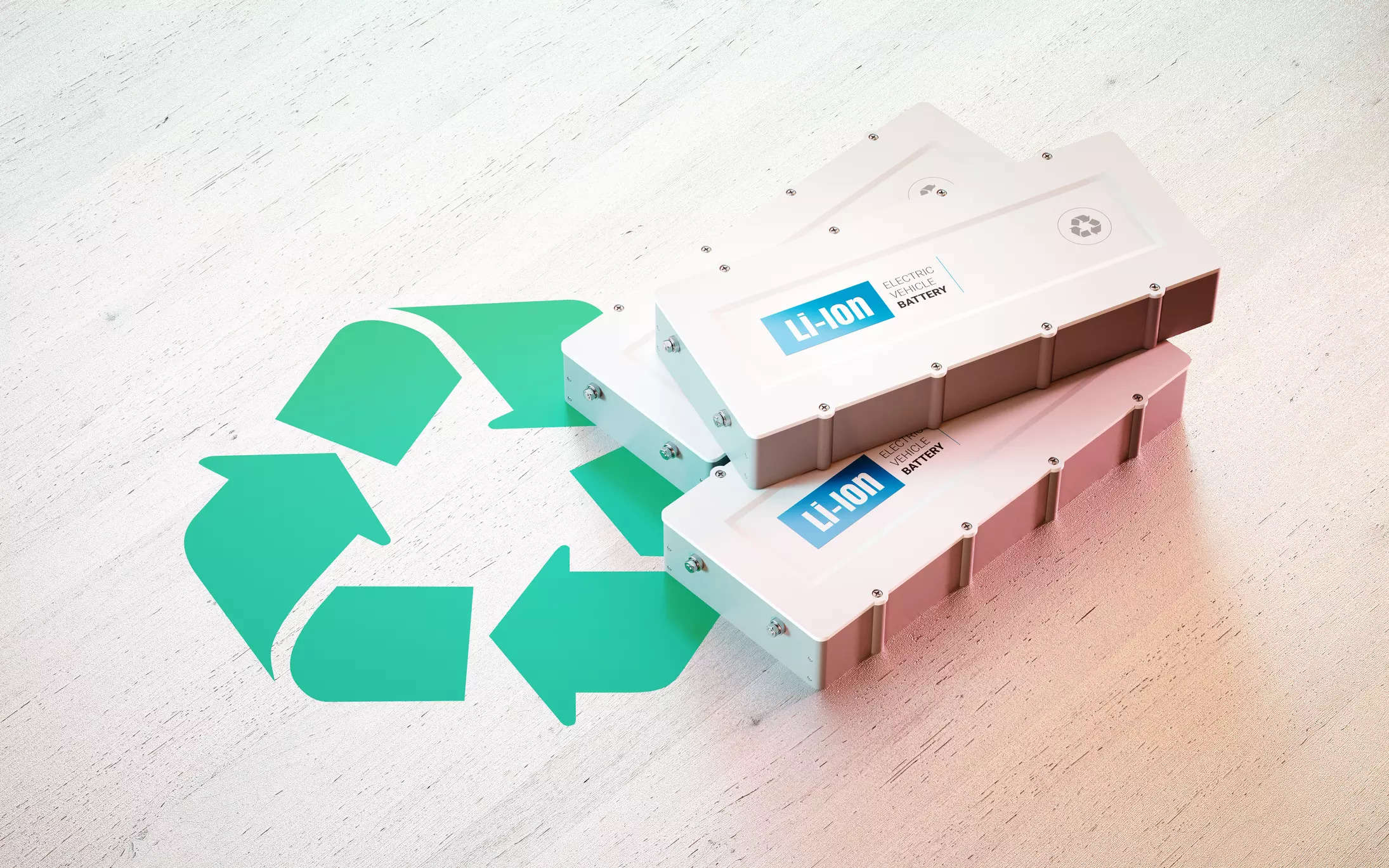

E-waste recycling agency Attero is planning to take a position INR 300 crore in a bid to extend its present lithium-ion battery recycling capability by 11 occasions to 11,000 tons by the top of 2022, a prime firm official stated. Based on the market estimates, India generates greater than 50,000 tons of lithium-ion battery waste yearly and it’s rising within the vary of 40-80 per cent relying on totally different fashions used for computing electrical car development in India, Attero Recycling CEO and co-founder Nitin Gupta informed PTI.“By the top of 2022, we can be round 22 per cent of the present market dimension. When it comes to tons, will probably be 11,000 tons. We’re making contemporary investments and can quickly have a big quantity of funding to construct up this capability… We’re planning to take a position near round INR 300 crore,” he stated.

Along with lithium-ion recycling capability, the corporate has earlier introduced to ramp up its total digital waste recycling capability by greater than double to three lakh metric tons by the top of 2022, from 1.44 lakh metric tons.

Gupta stated that by transitioning to electrical autos, India will save foreign exchange spent on petrol import from the Center East together with expenditure on importing lithium-ion batteries from China which is an even bigger concern.

“In our opinion, by making certain that the recycling infrastructure within the nation can develop and meet India’s present native demand and make India self-sufficient in battery supplies is what we’re working in the direction of.

“In that perspective, we’re growing our recycling capability for lithium-ion batteries by 11 occasions by placing up a further 10,000 tons every year capability from the present capability of 1,000 tonnes every year and can proceed to develop this capability,” Gupta stated.

Lithium-ion batteries flip hazardous after they come in the direction of the top of life and have to be handled in an environmentally pleasant method. Nearly 30 per cent of the worth of a lithium-ion battery cell is the worth of metals which make it up, which embrace cobalt, lithium, nickel, and graphite.

“Nearly 70 per cent of the world’s cobalt as we speak is mined within the DR Congo area, which is thought for youngster labour, terrorists regimes and so forth. On the present consumption charge, the world will run out of cobalt by 2030.

“Subsequently, recycling lithium-ion batteries, and extracting cobalt and reusing cobalt in battery manufacturing will not be solely factor to do from an environmental perspective, but additionally provide safety points,” he stated.

Gupta stated that just about 60 per cent of the world’s lithium is mined within the Bolivia Argentina triangle, which can be thought of the world’s driest area and the normal lithium mining is a water guzzling course of.

“To extract one ton of lithium utilizing a standard lithium mining course of requires greater than 500,000 gallons of water, which creates an entire quantity of ecological points and social points across the area as effectively,” he stated.

The corporate is taking a look at turning into a giant participant in not solely recycling lithium-ion batteries but additionally turning into a big participant within the provide chain of crucial supplies, which embrace cobalt, Lithium, Graphite, and Nickel.

“Now we have a industrial plant working for the final two years, the place we’re recycling all types of lithium-ion batteries starting from a cellular phone all the way in which to an electrical bus with weights starting from 30 grams to 780 kilogram. We’re extracting pure battery grade cobalt and pure pharmaceutical grade lithium carbonate which is used as a depressant in medicine,” Gupta stated.

Additionally Learn: