By Swathi Ramaswamy

A mean electrical car (EV) person has no thought about Discipline-Oriented Management (FOC) algorithm that works silently below the hood. However individuals within the know of issues will swear by its capability to drive electrical motors with utmost effectivity and accuracy. Although FOC shouldn’t be particular to EV motor management, its implementation within the automotive area requires particular abilities and experience. It entails a gamut of advanced calculations that get fairly difficult at occasions. Whether or not it’s Park and Clarke rework or the area vector modulation, implementation of FOC algorithm is a coder’s nightmare.

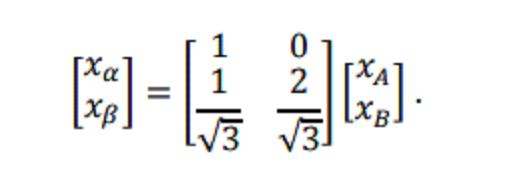

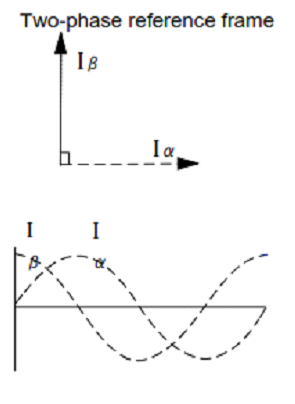

Pattern this: The Clarke transformation modifications a three-phase system right into a two-phase system with orthogonal axes in the identical stationary reference body. The brand new two-phase variables are denoted as α and β.

Because of the Mannequin Primarily based Design paradigm, implementation of FOC turns into loads simpler as code is generated by creating fashions. The difficult calculations just like the above one, are carried out by a set of block libraries and simulation methods that mannequin bodily motor management programs in a simulation surroundings.

There are two elements to FOC improvement for a motor management system. One, the place one mimics the management mannequin which is basically the FOC algorithm part. One other is the plant mannequin accountable for testing the algorithm in a simulated surroundings.

Pre-designed blocks

Improvement of FOC algorithm utilizing model-based design strategy entails creating and testing the algorithm in a simulation surroundings. As soon as the management algorithm mannequin is developed, it may be validated, and C code may be generated.

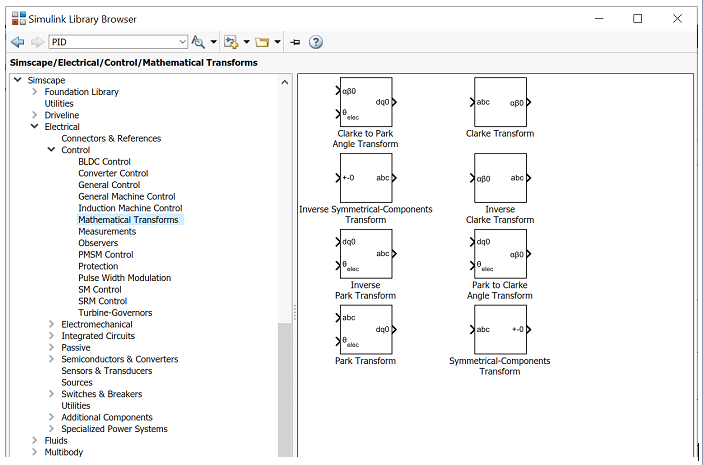

Essentially the most generally used surroundings for model-based improvement within the automotive area is MATLAB/SIMULINK. Modelling a bodily system within the Simulink surroundings is made even simpler with instruments like SIMSCAPE.

It has a set of block libraries and simulation options which can be extremely helpful in modeling bodily programs within the Simulink surroundings. These blocks signify fundamental mathematical operations to be carried out by the software program. Within the context of FOC algorithm improvement, the software gives blocks for Park and Clarke transformation in addition to area vector modulation.

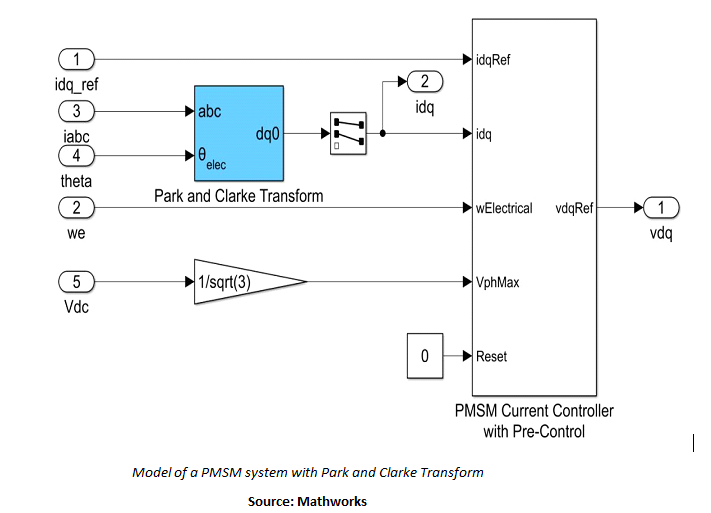

By connecting the required blocks, they get a diagram which is a mathematical mannequin representing the bodily system.

By taking the model-based design strategy, the engineers can create a illustration of the community of the system being designed. The diagram reveals that every system has numerous purposeful components that work together with one another through ports. The connection between every aspect is analogous to the bodily connection within the corresponding bodily system. Within the context of a brushless DC electrical present (BLDC) motor management system, these connections may be between the place sensors and the inverter, PID controller and so forth.

Modelling works on the precept that if bodily components of a system may be related, their fashions may be related as nicely.

Pre-designed blocks for creating and tuning field-oriented management for BLDC motors make the job simpler for engineers. Blocks embody Park and Clarke transforms, discipline weakening, a space-vector generator, Auto PID tune and few others. Within the modelling surroundings, these blocks may be configured as per the required motor-inverter or management algorithm for the motor-inverter. As soon as the management mannequin is developed by connecting the blocks, we will simply confirm the management algorithms in closed-loop simulation (plant mannequin) the place motors and inverters are additionally represented as fashions.

As soon as the management mannequin is developed by connecting the blocks, we will simply confirm the management algorithms in closed-loop simulation (plant mannequin) the place motors and inverters are additionally represented as fashions~

How does MBD assist?

Utilizing the MBD strategy implies creating fashions that mimic the management system. The next traces reply the query: what precisely does the FOC algorithm require and the way does MBD assist fulfill it?

When engineers develop FOC algorithm for a BLDC motor management, they basically:

- Design algorithm for Proportional Integral (PI) controllers for suggestions indicators.

- Overcome velocity error by tuning the good points of PI controllers

- Design an area vector modulator to manage the PWM sign fed to the inverter

- Develop discipline weakening management algorithm with a view to regenerate Iq_ref and Id_ref because the enter to PI controllers

- Implement Park, Inverse Park and Clarke rework

When model-based design together with all its instruments and applied sciences come into the image, most of those duties get simpler. From designing and testing to tuning the management algorithm, all actions are carried out in a simulation surroundings.

- With MBD on the helm, the engineers can:

- Mannequin present and velocity controllers in addition to the space-vector modulators and inverters

- Create a plant mannequin with a motor-inverter which may very well be used throughout numerous programs by configuring/altering the specs.

- Tune PI good points simply utilizing methods equivalent to automated tuning and linear management design methods like Bode plot

- Implement Park and Clarke rework utilizing Simulink blocks that simply must be configured primarily based on particular parameters

- Design sign conditioning and processing algorithms with a lot ease

- Take a look at the motor operation utilizing the FOC algorithm in a closed-loop simulation earlier than the {hardware} is prepared

- Generate automated C code for prototyping, HIL Testing, and so on. from the management mannequin.

Steps concerned in creating bodily mannequin

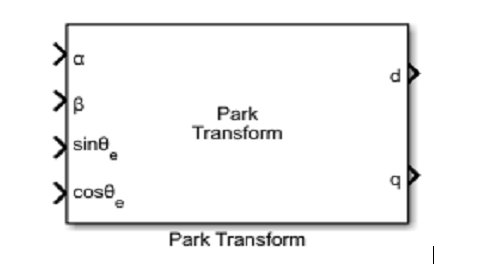

When making a bodily mannequin, power stream is an important facet to know. Every aspect in a bodily mannequin is related through ports that permit power switch. Within the case of a Park Remodel block (proven within the diagram beneath), there are 6 ports, 4 for inputs and a couple of for outputs.

Since SIMSCAPE is probably the most broadly used software for modeling, the steps adopted in SIMSCAPE software are examined right here.

Step 1: Step one is to create a brand new mannequin utilizing ssc_new.Creates mannequin with default settings which must be up to date additional earlier than code technology. Generally used blocks are made obtainable on the canvas.

Step 2: Assembling the bodily system is the subsequent step. It begins by including the required blocks from the library and including to the mannequin. The traces that join the blocks signify the precise bodily connection.

Step 3: The blocks within the SIMSCAPE libraries have default values for variables and parameters. These values primarily based on the info sheet of the motors, inverters, and so on. can simply be adjusted.

Step 4: The sensors at play within the bodily system are added to the mannequin. For a BLDC motor management scheme, a hall-effect sensor may be added for sensing the rotor place and feeding it to the PI controller. Enter and output masses in addition to sensor blocks are supplied by the software and may be added to the mannequin in both collection or parallel connection, relying on the amount to be measured.

Step 5: When each management mannequin and plant mannequin are prepared, the developed management is simulated. The solver configured in step one will consider the mannequin and run the simulation.

Shut to six months’ value of improvement and testing effort may be decreased through the use of MBD for FOC improvement. And on high of that, the motor management system may be examined even earlier than the {hardware} is prepared!~

The underside line

An environment friendly motor management system utilises the FOC algorithm in some type or the opposite. And getting this algorithm proper is a tricky nut to crack. When engineers strategy FOC utilizing model-based design paradigm, issues develop into simpler. Shut to six months’ value of improvement and testing effort may be decreased through the use of MBD for FOC improvement. And on high of that, the motor management system may be examined even earlier than the {hardware} is prepared!

What one will get on the last stage is a fool-proof motor management system to drive one’s electrical car programme or construct the perfect powertrain within the business.

Observe: The creator is Swathi Ramaswamy, Embitel Applied sciences, which is a part of the Volkswagen group of corporations.

DISCLAIMER: The views expressed are solely of the creator and ETAuto.com doesn’t essentially subscribe to it. ETAuto.com shall not be accountable for any injury precipitated to any particular person/organisation straight or not directly.)