By Anirban Ghosh

By Anirban GhoshThe next are the edited excerpts from the presentation.

The industrial automobiles trade gamers face massive challenges as a result of the automobiles are their incomes machines. The homeowners have to manage all of the components of the price linked with the automobiles like finance, gasoline, tyres, payload, uptime, the provision of the automobiles, compliance with the altering laws and many others. Digital product improvement is the important thing to assembly these and different challenges of the CV trade. Using digital engineering isn’t just for inner combustion engine automobiles but in addition for electrical mobility which goes to be the way forward for the trade.

Gas is the best price issue not like in lots of different nations. In comparison with 38% in India it’s only 10% in Europe. For the BS-VI gasoline compliance, digital product improvement was the important thing that got here to our assist. It ensured that inside a small window of improvement time, we might guarantee BS-VI compliance of the brand new automobiles of VECV. With assist from the Volvo group, we launched a number of new variants available in the market.

Advantages of digital product improvement

The advantages of digital product improvement embrace a sturdy design idea earlier than investing in bodily idea, early verification of car efficiency, decreased variety of prototypes leading to fewer prices and time to market. The time to market may be decreased by 30% by following digital simulation and testing processes.

For the interior combustion engine automobiles, petrol, CNG or diesel, digital product improvement assist in gasoline effectivity (engine and driveline evaluation), emissions (EATS optimization), sturdiness evaluation of car programs and powertrain, drive productiveness (experience management, dealing with, NVH evaluation), crash and security evaluation and payload optimisation.

For gasoline effectivity at VECV, the entire automobile has been modelled on the simulation together with driving cycle, atmosphere, automobile mannequin aggregating with engine mannequin, aerodynamic of the tyres and so forth. With digital engineering, now we have been capable of set up a correlation of as much as 96% between the digital validation of gasoline effectivity and the precise gasoline effectivity. Immediately, VECV provides merchandise which have 4%-10% higher gasoline effectivity than the competitors.

On the emission facet additionally, there may be digital engineering approach, digital EATS, what space to focus on, what’s the engine candy spot for increased effectivity and decrease emissions and the areas that must be focused and all of that is achieved on the digital testbed.

With digital engineering, now we have been capable of set up a correlation of as much as 96% between the digital validation of gasoline effectivity and the precise gasoline effectivity. Immediately, VECV provides merchandise which have 4%-10% higher gasoline effectivity than the competitors.Rajinder Singh Sachdeva, COO and head, R&D, VECV

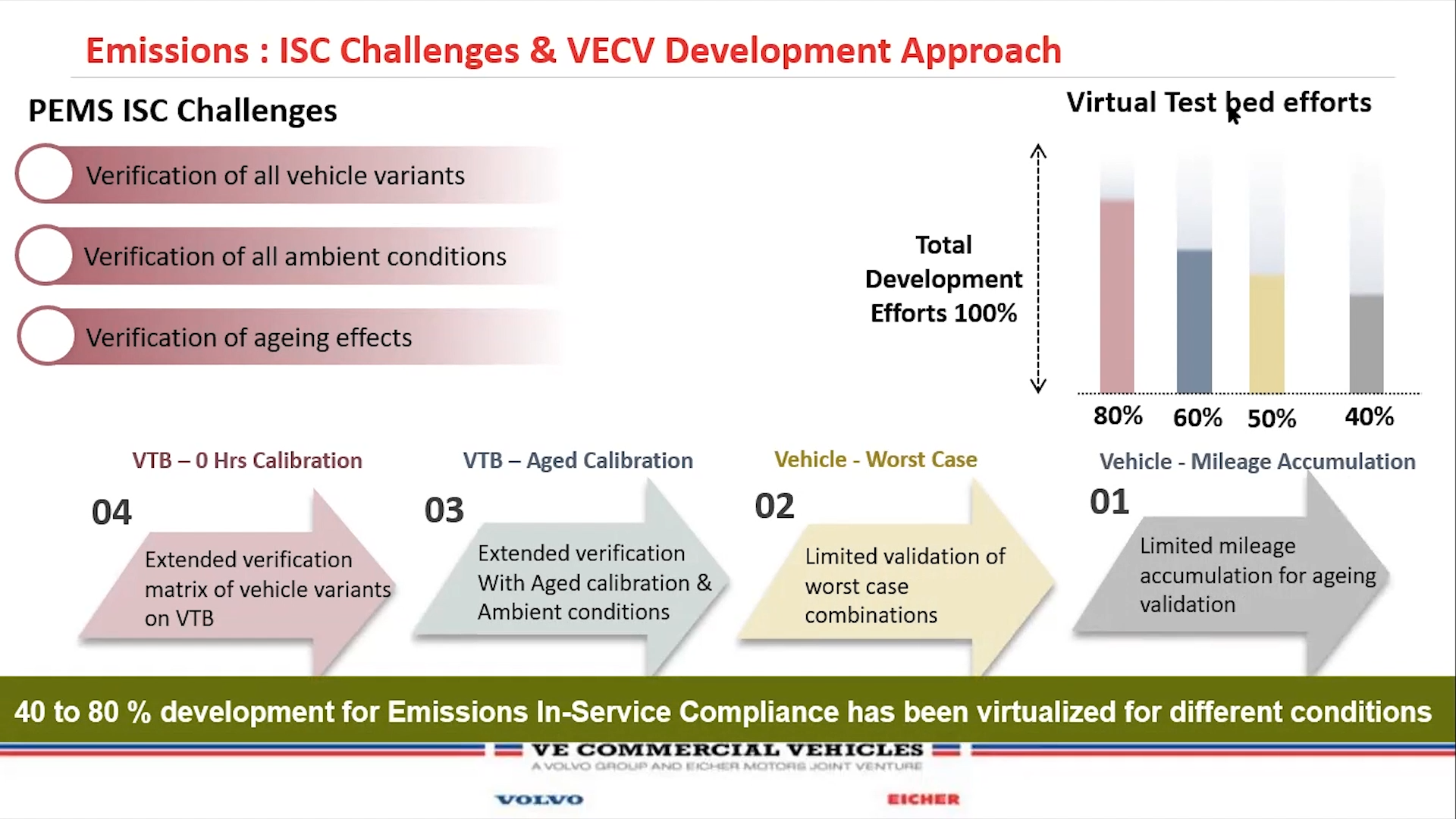

Equally, the actual driving emission cycles have gotten essential. In-service compliance, which is coming from BS-VI, ageing situations of the automobile at the moment are essential parameters alongside which a automobile high quality is measured. And right here now we have created prolonged verification metrics of various variants, aged calibration that’s accomplished on the digital testbed, restricted validation of worst-case mixtures are accomplished and after that, we do precise bodily testing. Right here we will see that 80% of our efforts are put in stage one, which is our calibration, 60% in aged calibration, 50% in restricted validations and solely 40% effort can be put into an precise bodily accumulation of mileage to make sure in-service compliance. So it is a enormous discount in time, effort and price, which ensures that throughout the variants there may be in-service compliance as per the BS-VI norms.

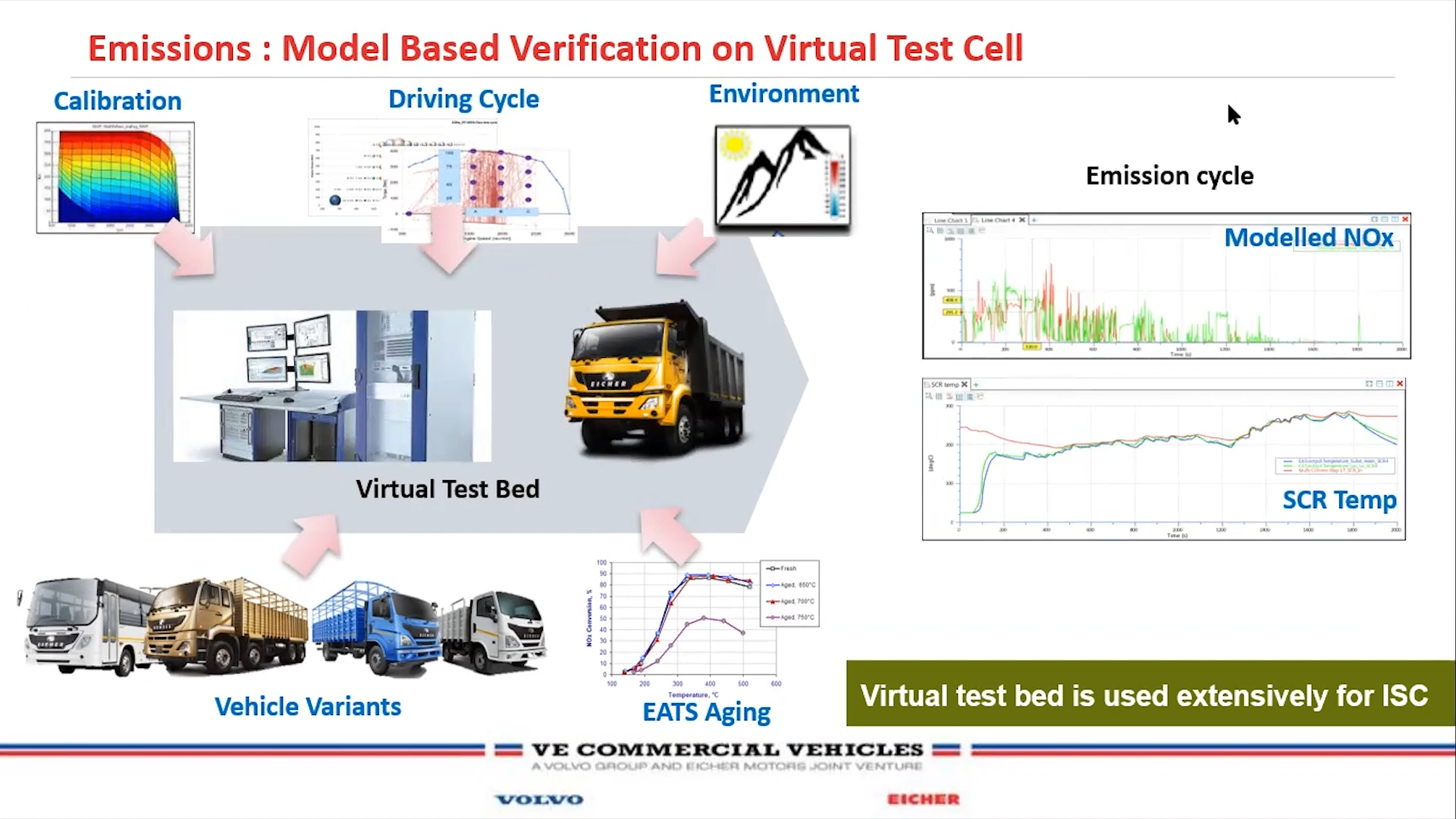

Mannequin-based verification on a digital testbed is finished on the automobiles. Totally different parameters are modelled like automobile calibration, atmosphere, driving cycle, EATS getting old, NOX emissions and SCR temp to make it possible for the automobile is wholly BS-VI compliant.

Equally for the engine, sturdiness and efficiency are additionally measured via the assorted simulation methods in order that promised automobile life is established. Even the transmission sturdiness, stability and efficiency are modelled on the simulator and examined.

Street profiles of varied Indian roads are fed within the simulation and the automobiles are examined for sturdiness, the harm is taken, chasis life, cabin life and many others. All of this may be achieved with none actual testing of the automobile. We will additionally guarantee most driver consolation utilizing the digital simulation in order that the motive force may be on the street for optimum hours.

The Indian automobile trade is shifting quickly and immediately virtually 70% of the entire automobile improvement may be accomplished nearly. Going ahead this can improve to 80%-85% of car improvement.Rajinder Singh Sachdeva, COO and head, R&D, VECV

Car dealing with, noise and vibration discount, steering, tyre life enchancment are all simulated nearly and these inputs go in direction of making the automobiles safer, snug and lasting longer. Extra the variety of kms a automobile is run, the extra revenue the proprietor earns. Even the security laws like crash assessments may be simulated in a digital atmosphere.

Loads of weight discount has been potential utilizing the digital improvement course of. Undesirable weight has been decreased in order that payload carrying capability is elevated.

Electrical automobile improvement

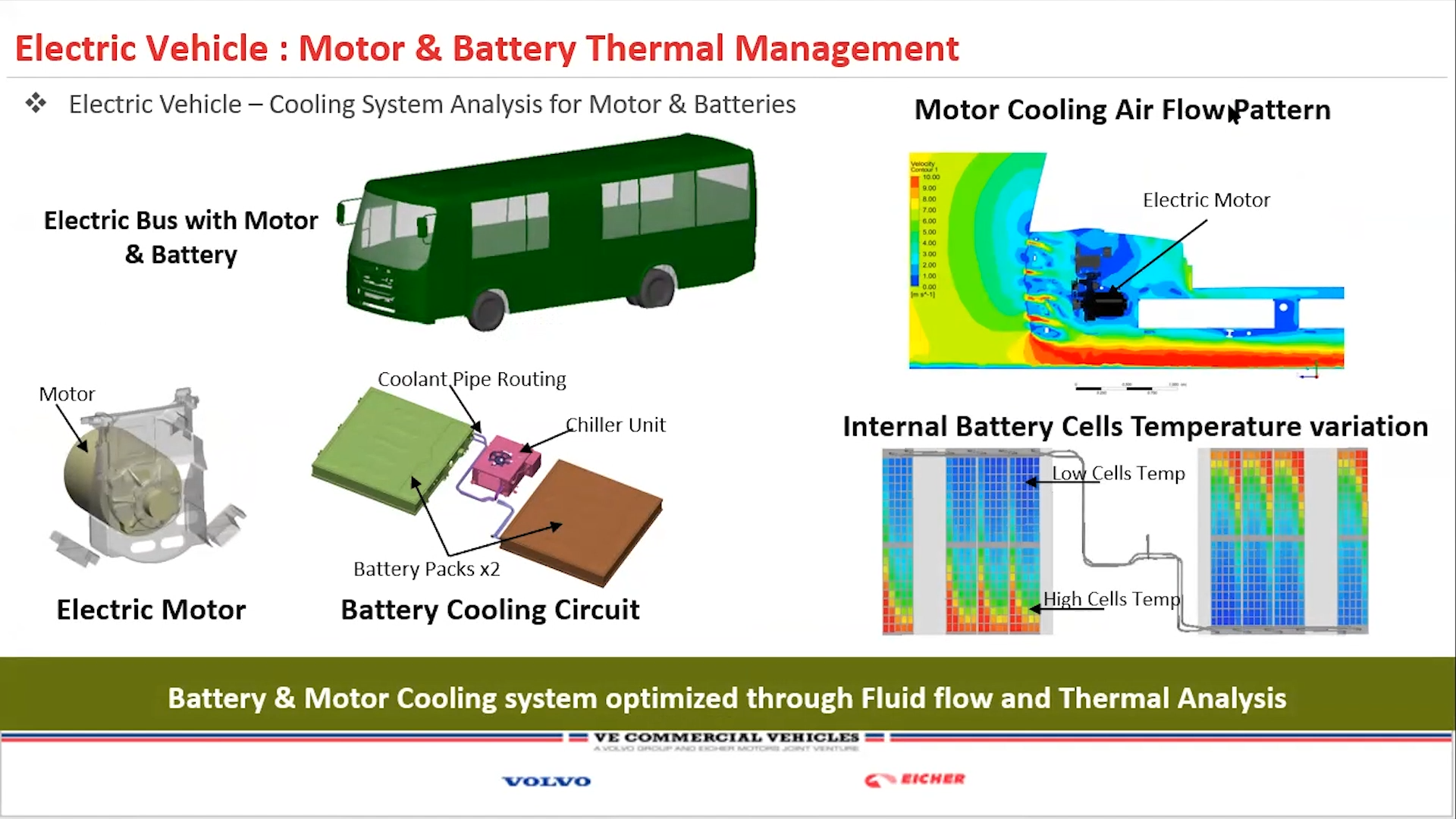

For electrical automobiles (EVs) digital product improvement has helped in simulating elements from electrical motors to battery cooling circuits. Motor cooling airflow sample and inner battery cell temperature variation have additionally been simulated. An entire electrical automobile may be modelled the place the management system, battery administration system, electrical automobile efficiency, automobile vary, and vary variance with temperature are analysed nearly within the lab and this ensures that the automobiles stand as much as buyer necessities.

Future challenges

Whereas virtually every part can now be simulated from engine effectivity to driver security, there are lots of challenges the CV trade has to face. Laws and norms are altering quickly and compliances have been elevated. Market dynamics are also quickly altering. Autos should be prepared for BS-VI step-II to be carried out in 2023, shift to electrical mobility, related automobiles or IoT- enabled automobiles, autonomous truck or self-driving truck improvement, FCEV automobiles and different challenges should be met by the CV trade.

To be able to meet all these challenges, digital product improvement is an funding that the CV trade can profit rather a lot from. The Indian automobile trade is shifting quickly and immediately virtually 70% of the entire automobile improvement may be accomplished nearly. Going ahead this can improve to 80%-85% of car improvement.

With this expertise, all buyer necessities may be delivered to the laboratory after which with out spending a lot time on the prototype and the funding, the necessities may be simulated to make sure that the uptime, gasoline effectivity and cargo capability of the automobile are most in order that income the proprietor earns from the automobile is most. That’s the solely approach to scale back logistical prices which is 12.5%-13% of the GDP. Product must be extra productive.