Automated guided automobiles, or AGVs, ship components to employees in a automobile manufacturing facility. Think about AGVs as robotic mail carriers, whizzing round magnetic tracks delivering components when wanted as automobiles are constructed. This implies a employee doesn’t waste time looking for a element and may keep targeted on putting in it. Saving time boosts a plant’s effectivity.

Automotive crops are busy locations and AGVs have turn into indispensable. At Nissan’s Oppama plant, south of Tokyo, there are greater than 700 AGVs. Peek inside Nissan’s automobile factories across the globe and also you’ll discover greater than 4,000 AGVs laborious at work. It’s an orchestra of alerts and sensors enjoying in excellent concord to keep away from bumps on the manufacturing facility ground.

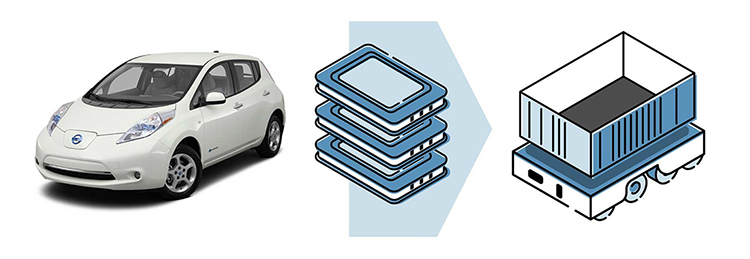

Nissan was exploring new methods to reuse its Nissan LEAF batteries, the mass-market electrical automobile that has spearheaded the corporate’s journey in direction of zero emissions since 2010. And the world of LEAF and AGV’s merged.

The primary-generation LEAF was fitted with a 24-kilowatt-hour battery pack. These lithium-ion packs had been made by combining 48 modules. About eight years in the past, Nissan’s engineers discovered a approach to take three of those modules, repackage them and match them inside an AGV. Final 12 months, they took this concept to a brand new stage through the use of repurposed battery modules, as a substitute of latest ones, to energy AGVs.

Nissan, along with 4R Power, has been a pioneer in giving batteries from electrical automobiles a brand new life in powering its AGVs – as a result of they weren’t highly effective sufficient anymore to run a automobile, however excellent for a machine scooting across the manufacturing facility. This makes electrification of mobility an much more sustainable proposition.

AGVs with the lithium-ion batteries, new or repurposed, cost quicker. Plus, employees now not must take out the batteries to plug them in. The AGVs merely cease momentarily on the charging station alongside their route and incrementally prime up at every passing. This automation saves an excessive amount of time.

The repurposed LEAF batteries additionally last more. Quite a bit longer. Whereas lead-acid batteries had been sometimes changed yearly or two, the repurposed LEAF batteries are anticipated to final seven to eight years. Fewer batteries means much less impression on the atmosphere and one other step in direction of being carbon impartial.

“Our prospects profit too. When used EV batteries turn into extra invaluable, trade-in costs rise” says Masashi Matsumoto, who promotes the event of AGVs at Nissan’s Manufacturing Expertise Analysis and Improvement Heart. “With extra methods to make use of batteries, the general residual worth of the LEAF has elevated.”

AGVs aren’t performed evolving. For now, every machine is sure to the magnetic path laid down for it at a manufacturing facility. Like a practice on a monitor, it could solely journey the place the tape permits it. Altering these routes – pulling up tape, laying new tracks and updating pc programmes – takes money and time.

However perhaps not for for much longer. Identical to the LEAF’s battery allowed AGVs to work longer, developments in autonomous driving may free manufacturing facility assistants from the magnetic tape. In a much more managed and predictable atmosphere, the AGVs would want much less expertise than automobiles, however may nonetheless depend on sensors and algorithms to maneuver round autonomously. Nissan can also be researching related expertise to permit AGVs to remain in fixed contact with the pc dealing with their actions.

“Utilizing our distinctive electric-driven and autonomous driving applied sciences to enhance AGVs will deliver main innovation to our factories,” says Matsumoto. “The availability of components in factories is coming into the age of electrification and automation.”

In order automobiles proceed to evolve, so will the factories making them.

Please click on right here to view the complete press launch.

SOURCE: Nissan