Ingenious concepts are available in many styles and sizes, however after they do, it’s usually the results of making use of some lateral considering to one thing that’s hiding in plain sight. So it was with Carbon Air, the British supplies firm, which noticed a possibility to enhance the journey high quality of air suspension utilizing a fabric constructed from coconuts that can be utilized to boost the efficiency of audio system loudspeakers. The fabric is activated carbon and, aside from coconut shells, it may be produced from different natural sources reminiscent of nutshells and wooden.

Air sprints work, because the identify suggests, through the use of compressed air in a cylinder as a spring. The benefit is that they supply a smoother journey than metal coil springs, with added advantages reminiscent of having the ability to fluctuate the journey peak to enhance aerodynamics, cowl tough terrain and make entry to the car simpler.

Air springs are extraordinarily efficient in premium automobiles however are nonetheless restricted by the legal guidelines of physics. Because the suspension deflects and the air within the spring turns into extra compressed, the spring price rises and the air spring turns into stiffer. A thumb over the tip of a bicycle pump demonstrates how this works. Push the plunger in and it’s simple at first, however close to the tip of the throw, extra power is required. Launch a few of the stress along with your thumb and the sensation of springiness comes again as the amount of air is decreased.

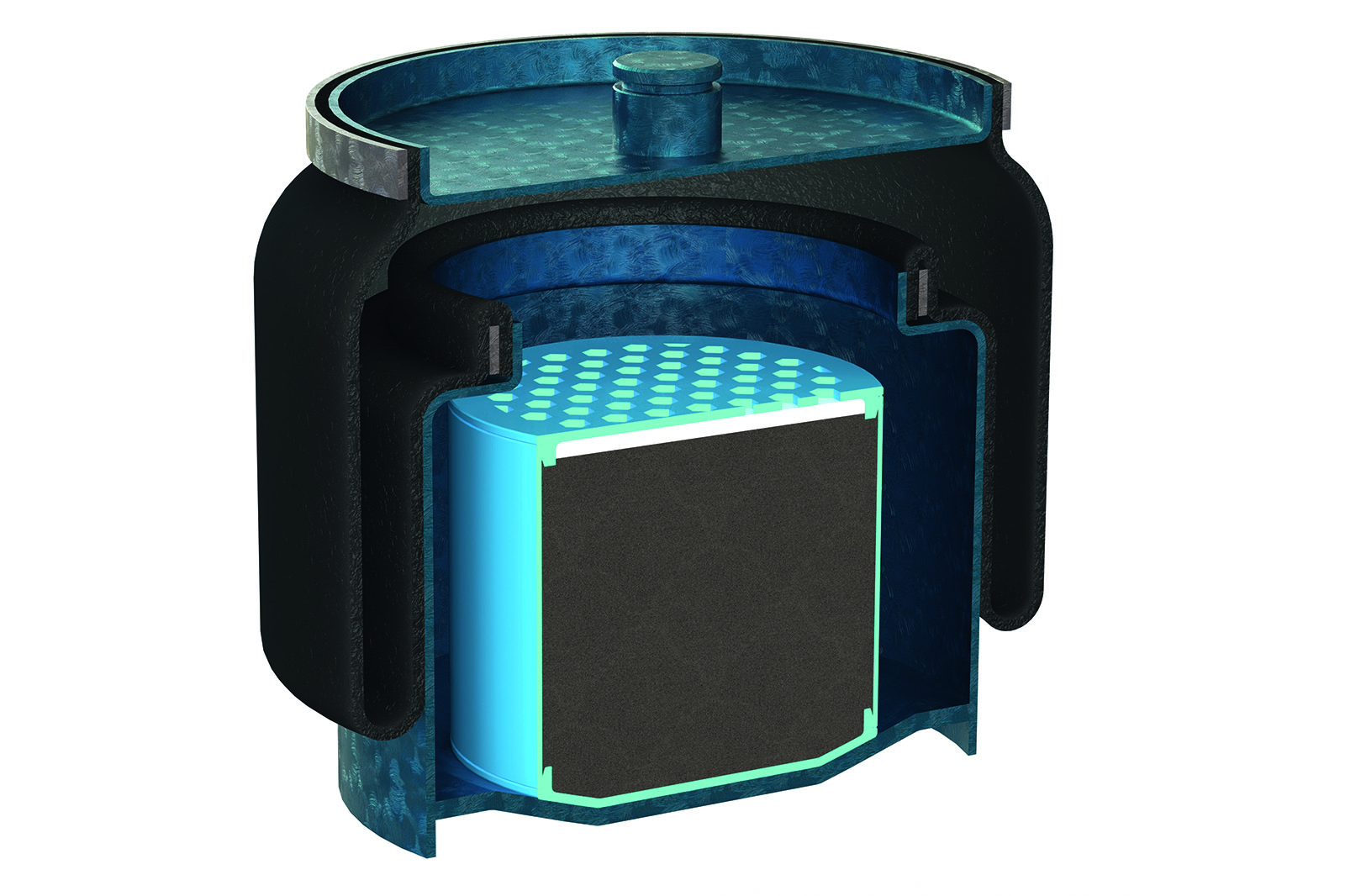

With an air spring, the larger the suspension motion, the stiffer the spring and the more durable the journey. Letting air out of the spring isn’t an possibility however there’s a method of manufacturing the same impact and that’s what Carbon Air’s expertise does. Activated carbon contained in the air spring can adsorb (versus take up) air molecules because the stress is elevated, lowering the amount of air contained in the spring. Due to that, the compliance of the spring is decreased because the suspension is compressed, giving a a lot smoother journey via the entire of the suspension journey.

Adsorbing means a layer of air molecules quickly adheres to the floor of the activated carbon, quite than turning into soaked up by the fabric (absorbed). Underneath a microscope, activated carbon is a large labyrinth of pores with an enormous floor space for the fuel molecules to be adsorbed on to. When this occurs, the adsorbed air is successfully taken out of the equation as if it has been bled off from the air spring. Besides it hasn’t.

Carbon Air has patented the thought and licensed it non-exclusively to a serious suspension producer that provides air suspension to Audi. Air suspension-equipped Audi A6s and A7s have it however the expertise can also be out there for licence to any firm that wishes it.

Carbon Air expertise can also be being utilized in mountain bikes and motocross bikes and talks are ongoing with audio producers for shrinking giant bass audio system and woofers with out affecting the standard of the sound.

3D printing for manufacturing

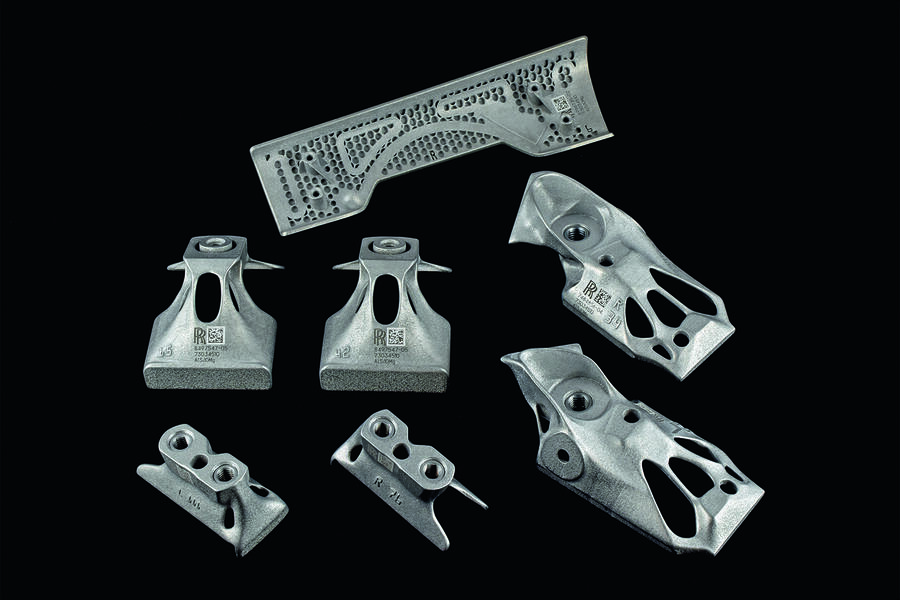

BMW is one among various producers shifting from speedy prototyping of components utilizing 3D printing to manufacturing precise manufacturing elements. Lighter 3D-printed metallic and polymer components that may be too complicated to make utilizing conventional machining strategies have been made for Rolls-Royce automobiles for the reason that center of 2020.