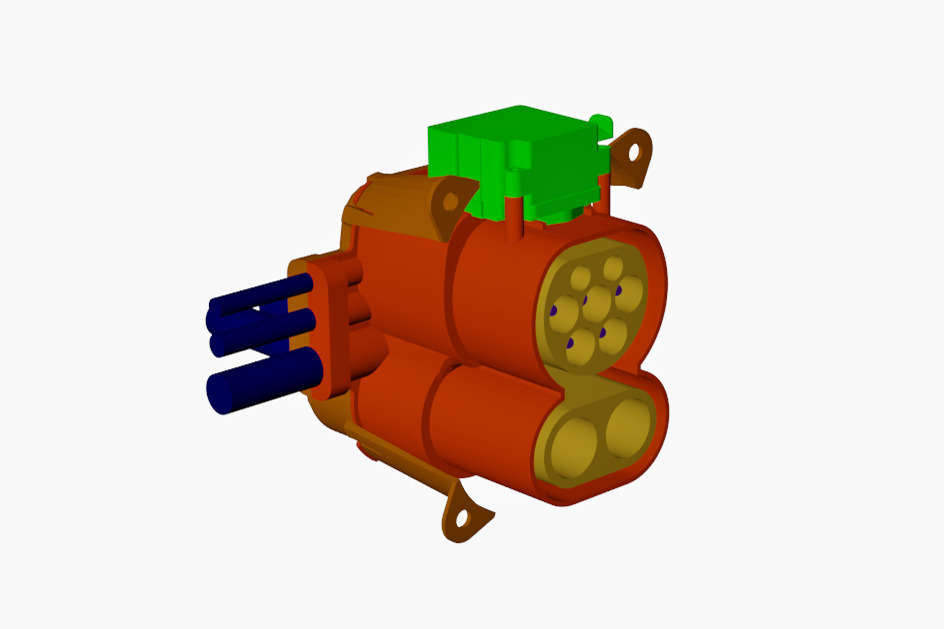

New Delhi: German specialty chemical compounds firm LANXESS on Tuesday launched a brand new design idea for charging inlets. These are put in in battery electrical automobiles and so they can accommodate the charging coupler of the exterior charging station.

“Our strategy is geared toward utilizing a modular configuration to get the precise materials in the precise place to satisfy the complicated necessities relevant to the assorted elements with the utmost precision,” Gregor Jaschkewitz, utility developer on the Excessive Efficiency Supplies (HPM) enterprise unit, who devised the design, stated in a media launch.

“On the identical time, a excessive degree of useful integration is meant to make it as simple as attainable to assemble all the unit, which implies screwless meeting and minimal elements with a purpose to maintain prices low,” he added.

Built-in thermal administration

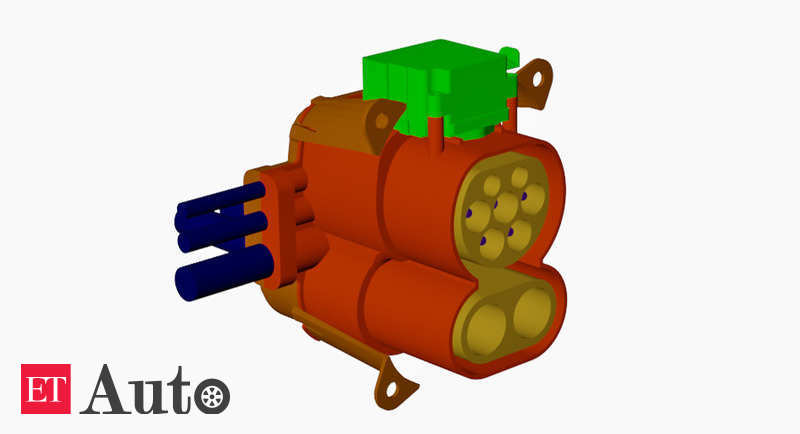

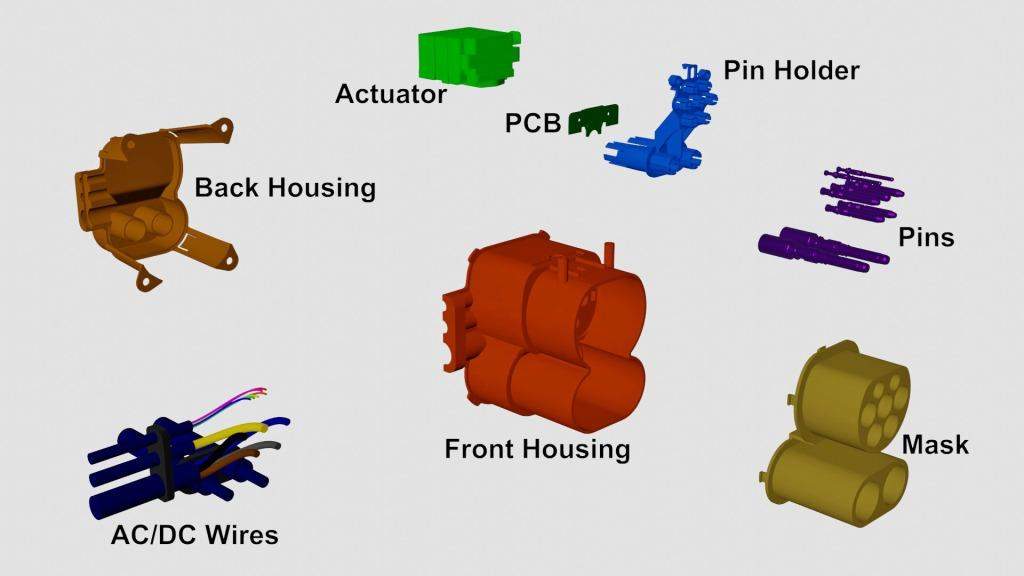

The important thing parts of this charging inlet design are the entrance and rear housings, a socket for the connector from the charging station and an actuator. The latter locks the connector in place to stop it from being unintentionally or intentionally pulled out in the course of the charging course of. “The pin holder holds the metallic connector pins in place, in addition to a printed circuit board (PCB) with cables for charging with direct or alternating present, amongst others. The pin holder helps thermal administration and thus makes quick charging at excessive currents simpler,” Jaschkewitz stated.

He stated “The flexibility to affix the elements with out the necessity for screws simplifies the meeting course of and related logistics, which, in flip, cuts manufacturing prices.”

Excessive materials necessities fulfilled

Plastics for charging inlets are required to ship excessive electrical insulation resistance in addition to excessive dielectric power and monitoring resistance. “Our materials options embody compounds which are ideally suited to this vary of necessities. In some instances, variations developed particularly for electrical automobiles are additionally accessible,” Sarah Luers, utility developer at HPM, stated.

“This consists of, for instance, extremely weather- and UV-resistant merchandise for housings in addition to supplies exhibiting low shrinkage and warpage for elements that have to be notably dimensionally secure. Thermally conductive polyamide 6 compounds with good mechanical properties are supposed to be used within the pin holder, which is topic to heavy thermal hundreds,” Luers added.

Help in element design

LANXESS assists charging system producers with an intensive vary of companies by way of its HiAnt service model. It calculates and simulates how element geometry and materials will have an effect on the technology of warmth within the element. Different companies embody performing essential flammability testing in compliance with requirements and conducting mechanical testing resembling ball drop checks, an organization launch stated.

Design for charging plug underneath means

The corporate is at present contemplating making use of the brand new design to additional assemblies of the charging infrastructure – such because the charging plug. The design and supplies experience constructed up in the course of the work on the car charging inlets might be deployed to a big extent as a result of the necessities are very related, the discharge added.